Torque Limiter

Torque limiters are safety devices that limit the torque transmitted in a drive system by slipping when torque demand exceeds a preset value, due to sudden impacts, overloads or machine jams. When the over load torque has passed, it automatically reengages, no resetting is required. The torque limiter protects the machine and reduces costly downtime. Torque limiters operate by using spring-loaded friction surfaces, slip torque is set by adjusting the spring force. The Torque limiter can be used as a center member clamped between two friction facings with a sprocket, gear, sheave, or flange plate.

Chain couplings are compact, durable components made of steel that connect two shafts to transmit power efficiently. They are designed to handle high torque while taking up very little space, making them an economical choice for power transmission. Their simple design makes them easy to install and remove, saving time and effort.

The sprockets in these couplings are identical, which helps maintain balance during operation and minimizes vibration. The flexible roller chain, along with the gap between the chain rollers and sprocket teeth, allows for slight misalignments and some movement of the shafts.

Standard sizes of these couplings are usually sufficient for most power transmission needs. However, custom couplings can be made to order for specific applications. If you need a recommendation or quote for a custom coupling, please provide complete details such as horsepower, RPM, hub dimensions, bore and keyway sizes, and the general operating conditions.

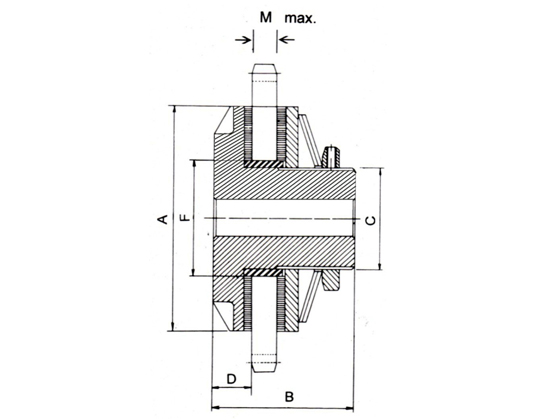

Capacities & Dimensions

| TORQUE LIMITER SIZE | TORQUE CAPACITY (KG. M.) | PILOT MIN. BORE | MAX. BORE | APPROX Wt. Kg | A | B | C | D | M. MAX. | 'F' SPROCKET BORE DIA. OVER BUSHING | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MIN. | MAX. | ||||||||||

| 50-1 | 0.3 | 1.5 | 8.0 | 14 | 0.3 | 50 | 29 | 24 | 4 | 7.2 | 30.10 |

| 50-2 | 0.6 | 2.5 | 8.0 | 14 | 0.3 | 50 | 29 | 24 | 6.5 | 7.2 | 30.10 |

| 65-1 | 0.7 | 2.8 | 10.0 | 22 | 0.5 | 65 | 50 | 35 | 15 | 8.8 | 41.40 |

| 65-2 | 1.4 | 5.5 | 10.0 | 22 | 0.5 | 65 | 50 | 35 | 15 | 8.8 | 41.40 |

| 90-1 | 2.0 | 7.0 | 12.0 | 28 | 1.5 | 90 | 65 | 45 | 18 | 16.0 | 52.00 |

| 90-2 | 3.5 | 14.0 | 12.0 | 28 | 1.5 | 90 | 65 | 45 | 18 | 16.0 | 52.00 |

| 125-1 | 5.0 | 18.0 | 16.0 | 38 | 3.5 | 125 | 78 | 60 | 23 | 16.0 | 70.00 |

| 125-2 | 6.5 | 36.0 | 16.0 | 38 | 3.5 | 125 | 78 | 60 | 23 | 16.0 | 70.00 |

| 150-1 | 7.5 | 44.0 | 20.0 | 42 | 5.5 | 150 | 90 | 70 | 26 | 23.0 | 80.00 |

| 150-2 | 9.0 | 61.0 | 20.0 | 42 | 5.5 | 150 | 90 | 70 | 26 | 23.0 | 80.00 |

| 180-1 | 11.0 | 58.0 | 25.0 | 64 | 10.0 | 180 | 110 | 100 | 28 | 28.5 | 110.00 |

| 180-2 | 20.0 | 110.0 | 25.0 | 64 | 10.0 | 180 | 110 | 100 | 28 | 28.5 | 110.00 |

| 225-1 | 22.0 | 140.0 | 25.0 | 92 | 20.0 | 230 | 120 | 140 | 33 | 28.5 | 152.00 |

| 225-2 | 40.0 | 175.0 | 25.0 | 92 | 20.0 | 230 | 120 | 140 | 33 | 28.5 | 152.00 |

Minimum size Sprockets to fit on Torque Limiters

| TL 50 | TL 65 | TL 90 | TL 125 | TL 150 | TL 180 | TL 225 |

|---|---|---|---|---|---|---|

| 6B 20T | 6B 25T | 6B 33T | 8B 35T | 8B 42T | 8B 48T | 8B 60T |

| 8B 16T | 8B 20T | 8B 30T | 10B 30T | 10B 34T | 10B 39T | 10B 50T |

| 10B 14T | 10B 16T | 10B 21T | 12B 25T | 12B 30T | 12B 33T | 12B 33T |

| 12B 19T | 16B 19T | 16B 22T | 16B 26T | 16B 26T | ||

| 16B 15T | 20B 19T | 20B 21T | 20B 32T | |||

| 24B 17T | 24B 18T | 24B 23T |

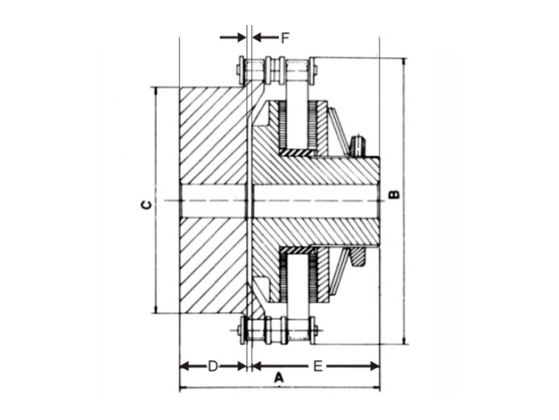

TORQUE LIMITER COUPLING

BV Transmission Offers a Torque Limiter Coupling in 14 different sizes. This coupling consists of a stock Torque Limiter and a roller chain type coupling.

The Torque Limiter coupling safeguards against overloads slip protection with the ability to driven shafts and couple driving. It is comprises of a standard Toque Limiter and a roller chain coupling. The Torque Limiter's center member is a stock ground plate sprocket that is coupled to a sprocket via an I.S. double strand roller chain which is easily connected using a standard connecting link. This design provides a reliable and simple-to-assemble flexible coupling that compensates for shaft misalignment.

| Misalignment | Torque capacity Kg. m. | Stock Min. Plain Bore | Max. Bore | Dimensions (mm) | Approx. wt. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Catalogue No. | Max.Parallel | Max.Angular | Min. | Max. | Cplg. Spkt (mm) | Torque Limiter | Cplg. Spkt (mm) | Torque Limiter (mm) | A | B | C | D | E | F | Kgs. |

| 50-1 C 5 0 - 2 C |

0.2 | 1/2° | 0.3 0.6 |

1.5 2.5 |

10 | 8 | 28 | 14 | 53 | 77 | 50 | 17 | 29 | 2 | 1.0 |

| 65-1 C 65 - 2 C |

0.25 | 1/2° | 0.7 1.4 |

2.8 5.6 |

10 | 10 | 48 | 22 | 78 | 100 | 74 | 30 | 50 | 3 | 2.0 |

| 90-1 & C 90 - 2 C |

0.30 | 1/2° | 2.0 3.5 |

7.0 14.0 |

19 | 12 | 56 | 28 | 107 | 136 | 100 | 45 | 65 | 3 | 6.50 |

| 125-1 C 125-2 C |

0.38 | 1/2° | 5.0 6.5 |

18.0 36.0 |

22 | 16 | 70 | 38 | 122 | 185 | 145 | 48 | 78 | 3 | 13.0 |

| 150-1 C 150-2 C |

0.38 | 1/2° | 7.5 9.0 |

44.0 61.0 |

25 | 20 | 90 | 42 | 141 | 214 | 168 | 48 | 90 | 3 | 21.0 |

| 180-1 C 180-2 C |

0.50 | 1/2° | 11.0 22.0 |

58.0 110.0 |

25 | 25 | 100 | 64 | 173 | 247 | 195 | 62 | 110 | 3 | 34.0 |

| 225-1C 225-2C |

0.50 | 1/2° | 20.0 40.0 |

140.0 175.0 |

40 | 25 | 160 | 92 | 204 | 309 | 244 | 82 | 120 | 3 | 65.0 |