TYPE - J/JE/JES/E

Flexible sleeves couplings come in four different materials viz (EPDM, Neoprene, Hytrel and Urethane). They also come in three different basic constructions. Characteristics of the materials are given below.

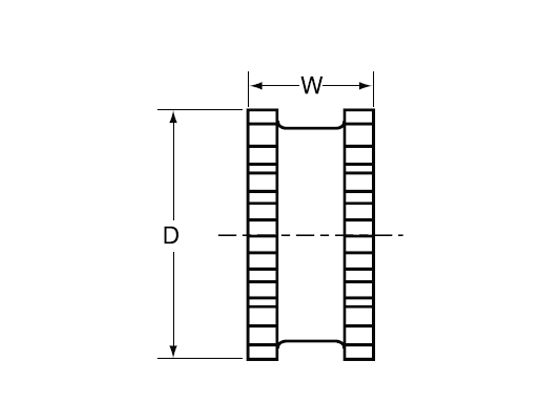

JE-JES-JN-JNS

J-type sleeves are molded EPDM rubber (E) or Neoprene (N), available in either one-piece solid construction (JE or JN) or one-piece split construction (JES or JNS). You can use these sleeves in any Sure-Flex Plus flange that fits within a specific size.

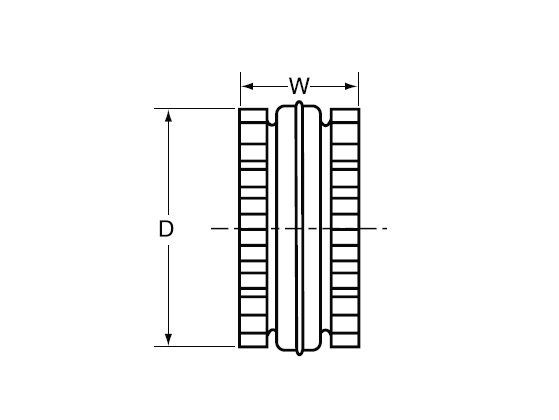

E-N

With a retaining ring, these sleeves are made of two pieces design. EPDM (E) or Neoprene (N) are the two available materials. You can use these sleeves with flange within a given size. Sleeves are shown here assembled and disassembled

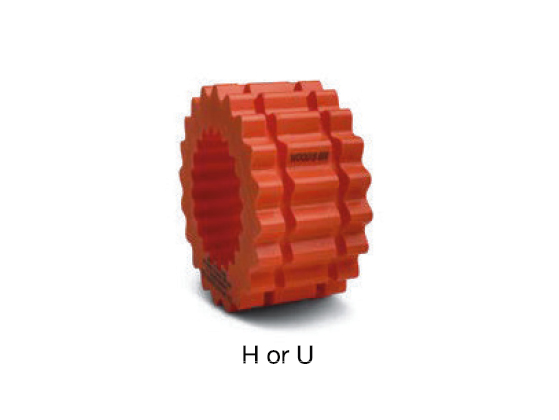

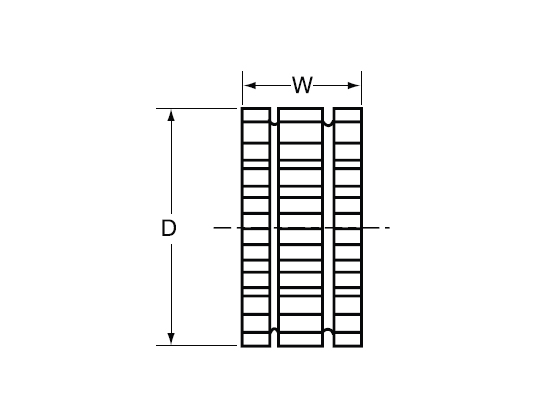

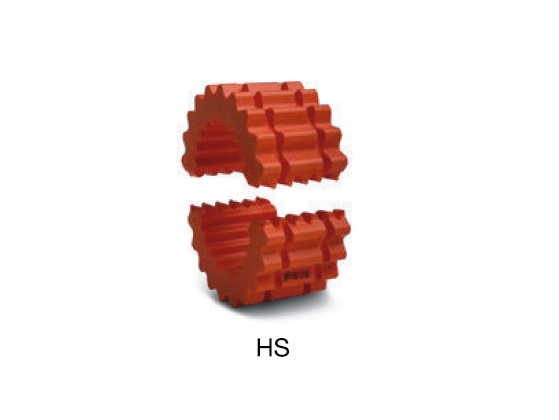

H-HS-U

Hytrel (H) and Urethane (U) sleeves, are made for high-torque applications transmit four times the power of an equivalent EPDM or Neoprene sleeve. Available in one piece solid construction (H or U) or two piece split construction (HS), these can be used only with S, C and SC flanges. They cannot be used with J or B flanges or as direct replacements for EPDM or Neoprene sleeves.

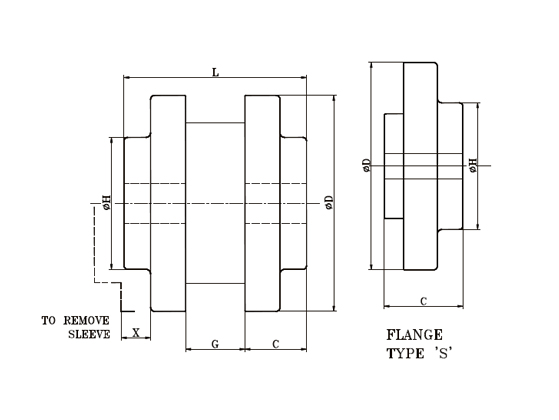

DIMENSIONS (in Inches)

| Coupling Size | JE, JES, JN & JNS Sleeves EPDM & Neoprene | E and N Sleeves EPDM & Neoprene | H, U & HS Sleeves Hytrel & Urethane | ||||||

|---|---|---|---|---|---|---|---|---|---|

| D | W | Weight(lbs.) | D | W | Weight(lbs.) | D | W | Weight(lbs.) | |

| 3 | 1-7/8 | 1 | .06 | - | 1 | - | - | - | - |

| 4 | 2-5/16 | 1-1/4 | .10 | 2-5/16 | 1-1/4 | .11 | - | - | - |

| 5 | 2-15/16 | 1-9/16 | .20 | 2-15/16 | 1-9/16 | .25 | - | - | - |

| 6 | 3-3/4 | 1-7/8 | .40 | 3-3/4 | 1-7/8 | .49 | 3-3/4 | 1-7/8 | .44 |

| 7 | 4-11/32 | 2-3/16 | .62 | 4-11/32 | 2-3/16 | .77 | 4-11/32 | 2-3/16 | .69 |

| 8 | 5-1/16 | 2-1/2 | 1.13 | 5-1/16 | 2-1/2 | 1.4 | 5-1/16 | 2-1/2 | 1.4 |

| 9 | 6 | 3 | 1.46 | 6 | 3 | 2.0 | 6 | 3 | 1.8 |

| 10 | 7-1/16 | 3-7/16 | 2.32 | 7-1/16 | 3-7/16 | 3.2 | 7-1/16 | 3-7/16 | 2.9 |

| 11 | - | - | - | 8-3/16 | 4 | 5.1 | 8-3/16 | 4 | 4.5 |

| 12 | - | - | - | 9-9/16 | 4-11/16 | 8.1 | 9-9/16 | 4-11/16 | 7.3 |

| 13 | - | - | - | 11-3/16 | 5-1/2 | 13.0 | 11-3/16 | 5-1/2 | 11.8 |

| 14 | - | - | - | 13-3/32 | 6-1/2 | 21.1 | 13-3/32 | 6-1/2 | 19.3 |

| 16 | - | - | - | 17-29/32 | 8-3/4 | 45.3 | - | - | - |

TYPE - J/JE/JES/E

All diamension in mm

| Coupling Size | Flange Type | Sleeve Type | kW @ 100 rpm | Rated Torque | Max Speed | Bore (mm) | Dimensions (mm) | W Weight | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N-m | rpm | P.B. | MAX. | C | D | G | H | L | X | Kg | ||||

| 3 | J | JE, JES | 0.08 | 7.64 | 9200 | 10 | 22 | 20 | 52 | 9 | 38 | 49 | 16 | 0.3 |

| 4 | J | 0.15 | 14.32 | 7600 | 13 | 25 | 22 | 63 | 16 | 41 | 60 | 16 | 0.5 | |

| 5 | J | 0.30 | 28.65 | 7600 | 13 | 29 | 26 | 83 | 18 | 48 | 70 | 23 | 1.1 | |

| S | 34 | 19 | 71 | 30 | ||||||||||

| 6 | J | 0.52 | 49.66 | 6000 | 16 | 35 | 33 | 102 | 22 | 63 | 88 | 28 | 2 | |

| S | 44 | 21 | 88 | 36 | ||||||||||

| 7 | S | 0.90 | 85.94 | 5250 | 16 | 48 | 47 | 118 | 25 | 71 | 100 | 34 | 2.8 | |

| 8 | S | 1.34 | 127.96 | 4500 | 19 | 54 | 53 | 138 | 28 | 98 | 112 | 38 | 4.8 | |

| 9 | S | 2.16 | 206.26 | 3750 | 22 | 64 | 61 | 161 | 36 | 98 | 128 | 45 | 7.2 | |

| 10 | S | 3.43 | 327.54 | 3600 | 29 | 73 | 69 | 191 | 41 | 111 | 144 | 51 | 11.2 | |

| 11 | S | E | 5.37 | 512.80 | 3600 | 32 | 87 | 87 | 219 | 48 | 133 | 180 | 61 | 18 |

| 12 | S | 8.50 | 811.69 | 2800 | 38 | 98 | 104 | 254 | 60 | 146 | 210 | 68 | 28 | |

| 13 | S | 13.43 | 1282.47 | 2400 | 51 | 100 | 111 | 299 | 68 | 171 | 235 | 78 | 48 | |